There are over 950,000 more manufacturing jobs in the U.S. today than in 2010. This resurgence presents a major opportunity for communities. As a segment of manufacturers turns away from the inefficiencies of sprawling suburban industrial parks and re-onshores production from overseas locations there is growing demand for urban locations. But cities that want to take advantage of manufacturing’s return need to be fully prepared. An EcoDistrict approach to industrial revitalization can help keep costs down and bring the benefits of manufacturing to a community, while reducing the environmental burdens.

Accepting the outdated norm in development and infrastructure will not serve us as we prepare our cities for climate and economic uncertainties. Instead, there must be a focus on the three “imperatives” of an EcoDistrict: Equity, Resilience, Climate Protection. Any district-scale strategy must have these as its fundamental building blocks. Within these imperatives, the EcoDistrict Protocol—a framework document for creating EcoDistricts—defines six priorities that projects should address: Place, Prosperity, Health & Wellbeing, Connectivity, Living Infrastructure, and Resource Restoration. Applying these principles to revitalizing manufacturing districts can help bring 21st century green, urban manufacturing jobs to communities.

CNT has researched a range of innovations for Industrial EcoDistricts in the areas of energy, water, and transportation. CNT’s work looks at district-scale interventions through the lenses of: What is it?, Why do it?, and What does it cost? with practical, real world examples and financing strategies to help implementers and decisionmakers create next-generation industrial districts in their communities. Specifically we looked at the following types of infrastructure:

- Energy—Renewables, Storage, District Energy, Microgrids, Energy Efficiency, and Demand Management

- Water—Water Efficiency, Demand Reduction, and Water Reuse

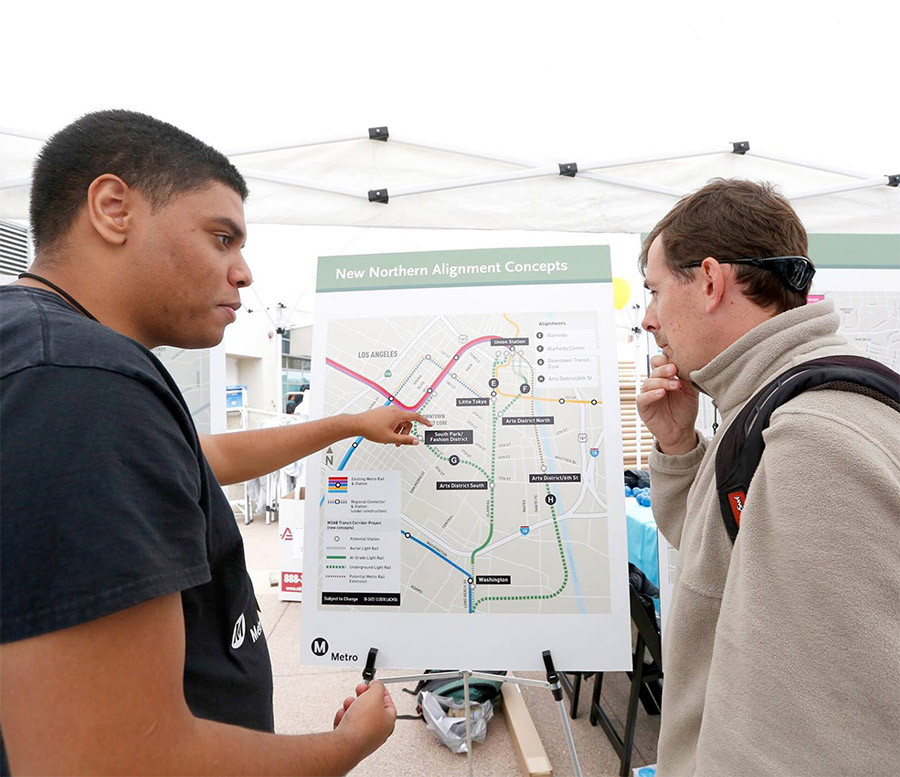

- Transportation—Urban, Transit-Served Locations, Goods Transportation, and Logistics

- Waste Systems

We also discuss the several essential implementation factors, including site selection, governance, engagement, financing, policy, and documenting benefits. In addition to preparing a primer, CNT presented our findings in a free webinar with EcoDistricts.

While all of the technologies analyzed in our research are currently utilized in one form or another, for the most part they have yet to be brought to scale. For example, our research overviewed San Francisco’s Health Ceramics Factory, a ceramic tile factory building that also houses a retail outlet, a demonstration kitchen, a Blue Bottle coffee shop, and an art gallery. This innovative combination of uses would not have been allowed under many traditional zoning schemes. But some “zoning yoga,” as one city staff member called it, allowed the manufacturer to locate in the city economically and serve as a destination for the community. As we begin to recognize our need for changing the way we grow and reimagine what infrastructure means in our communities, Industrial EcoDistricts present a way to create jobs while saving energy and water, addressing climate change, and creating an economic benefit for businesses and communities.

Strengthening Transit Through Community Partnerships

Strengthening Transit Through Community Partnerships